Our Crafts In Action

Welcome to our world where craftsmanship meets artistry to create exquisite watch straps and accessories that embody timely luxury, style, and unmatched attention to detail. Each watch strap and accessory is a handmade masterpiece crafted with passion and skill, combining exclusive materials, custom-designed hardware, and personalized touches.

Discover the meticulous process of our crafts; from gathering the finest materials and tools to the final touches, every crafting phase reflects the essence of our dedication to excellence. With every stitch, every detail, and every finishing touch, we are creating more than just a watch strap and a accessory; we are crafting a work of art that will adorn the wrists of discerning individuals who truly appreciate the true beauty of handmade craftsmanship.

Step 1

Select & Prepare

Perhaps the most important phase throughout our crafting process, that serves as a foundation on the overall look and feel of your strap. This phase begins with a filtered selection of only the finest range of full-grain leather, followed by a series of preparation to get the leather ready. Preparation includes pickling and neutralization for baterial removal, tanning for stabalizing and preservation, splitting and shaving to divide and even out the hides, and drying and conditioning to finish the preparation process. We understand that sustainability goes a long way, and we take pride in our leather selection practices. All our leathers are selected very carefully (we only accept leathers without heavy blemished or scarred).

Step 2

Measure & Cut

Accurate measurements are crucial to ensure a well-fitting strap. All straps are formed with separate layers (external, padding and internal) glued in one, with each layer measured with accurate precision before cuts are carefully performed to maintain a clean and consistent look. Speaking of consistency - we take it very seriously. Our cutting process only occurs when all our leather is pliable enough to be performed; with leather conditioners sometimes applied to more naturally dry vegetable-tanned leather to increase pliability, that would result in a more consistent and smooth cut throughout all our straps. Additional trims are also performed thereafter to maintain a consistent and refine look.

Step 3

Shape & Punch

With the strap now measured and cut, its time to shape the ends and punch holes. Shaping the ends of the straps can enhance the overall look and feel of the strap, giving it a nice finishing touch. By default, all straps would come finished with a tapered end, with a gradual decrease in strap width from the lug end, to give it a more sleek and versatile look. Punching of strap holes comes next. The holes are cleanly punched and smoothen to prevent fraying, needed for a seamless buckle or clasp attachment. All strap holes are punched with a round hole option, that is the default for all our straps.

Step 4

Bevel & Sand

Beveling and sanding the edges of the strap not only improves its aesthetic appeal but also prevents the edges from fraying and increases the overall durability of the strap. The beveling process is performed with the strap firmly secured with a stitching pony, elevated at exactly 45 degrees, positioned against the edge of the strap and the beveller. Thereafter, consistent pressure is applied to trim the edges. Using of a fine-grit sandpaper, sanding is performed through gentle and uniform strokes along the beveled edges, and performed continually until the edges are smooth to the touch without any roughness or uneveness.

Step 5

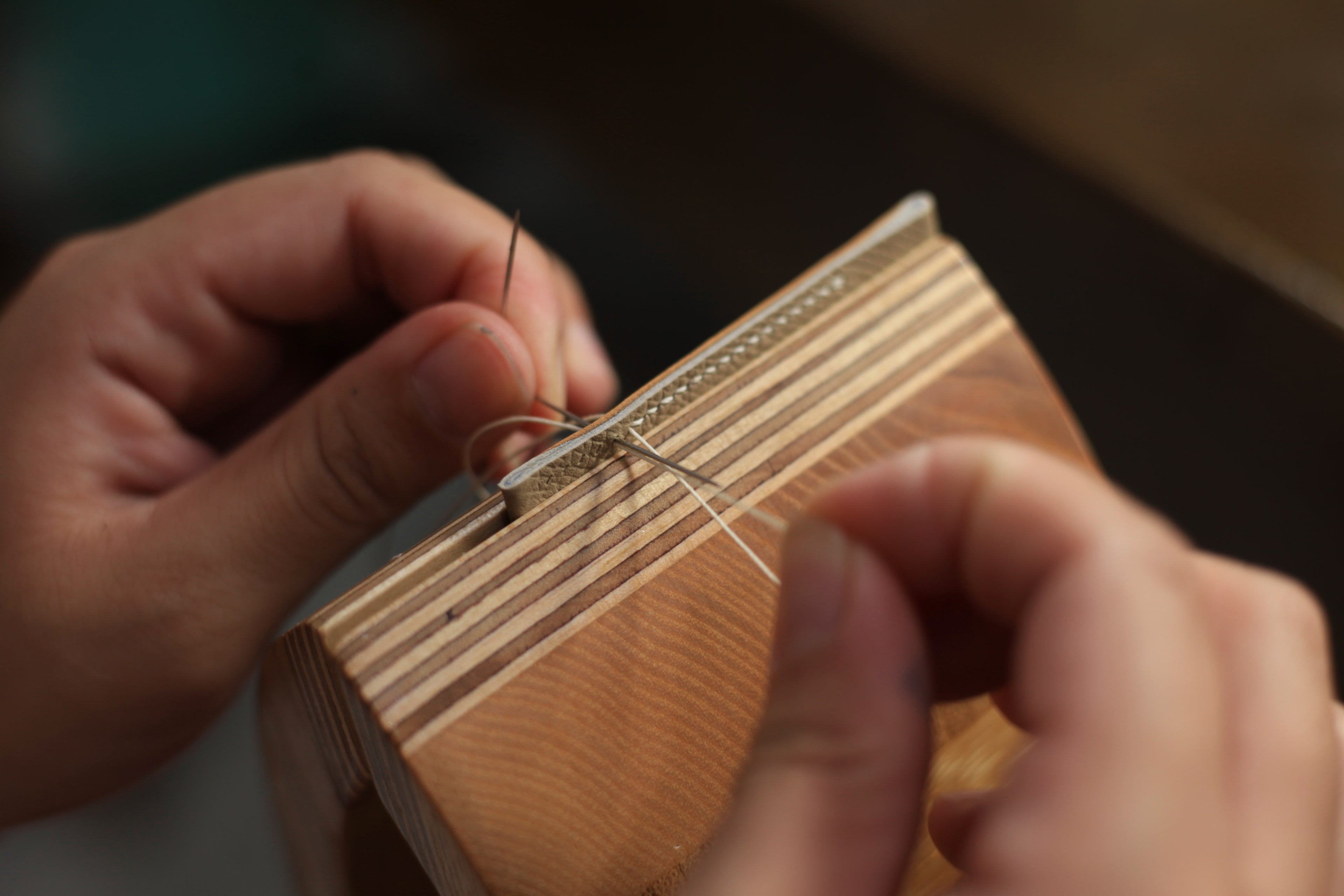

Stitch & Groove

Creating grooves along the edges of the strap where the stitching will be closely done serves multiple purposes. The groove helps to guide the punching of stitch holes, and the stitching of the needles and thread to ensure a straight and even stitching, while protecting the stitch from prolong wear and tear by securing it in place. Grooves are created by hand using a stitching groover tool; lightly pressured and pushed along the edges before stitching, and reinforced again after. All straps are saddled stitched by hand using two needles and a thread, that traverse both leather ends alternatively, and with a dual tie-off knots finished on the strap's end. This is also known to be the strongest and most lasting stitching technique.

Step 6

Edge Paint & Finish

The strap is bonded by an extremely durable and strong edge paint adhesive that doesn't just hold the strap in place and prevent fraying, but also eludes a touch of poise and luxury with its smooth and clean look. Thereafter, the keepers are then installed along with the strap's buckle and spring bars. Installing of these accessories are as crucial as crafting the strap itself due to the precise measurements needed to ensure a perfect fit. Finally, a small amount of moisture-resistant conditional is applied to bring out the strap's natural sheen, and to further extend the strap's lifespan.